General Engineering: General Engineering encompasses a broad range of disciplines that apply scientific and mathematical principles to design, develop, and maintain structures, machines, and processes. In a machining engineering business, general engineering services may involve designing and fabricating custom parts, repairing machinery, and offering consulting services to optimize manufacturing processes and improve efficiency.

Mould Machining: Mould machining is the process of creating intricate, high-precision tools and components used in the manufacture of plastic and metal parts. These moulds are typically used in injection moulding and die-casting processes to produce products ranging from automotive parts to consumer goods.

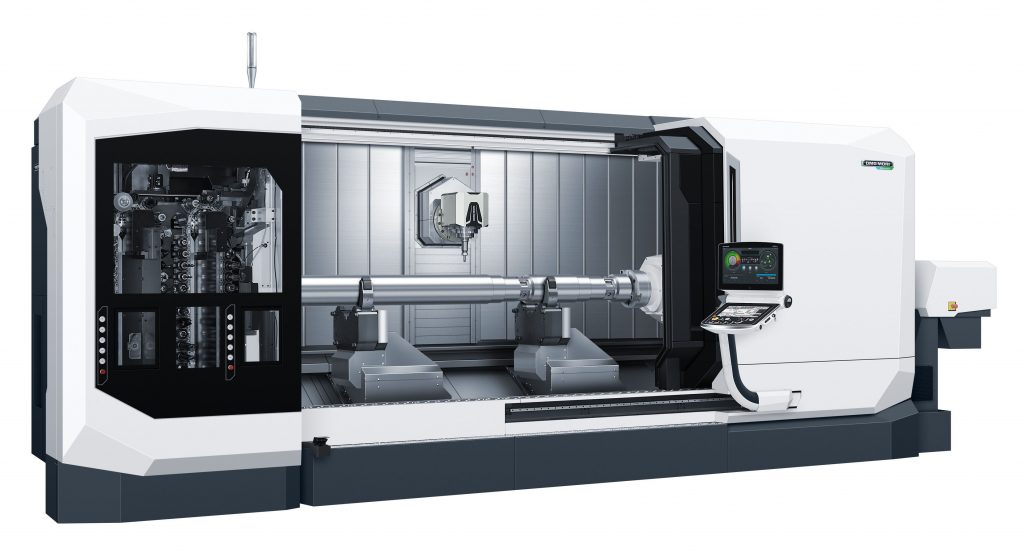

In a machining engineering business, mould machining services include designing, manufacturing, and maintaining complex moulds and tooling using advanced CNC machines, ensuring high-quality and accurate production.

4-Axis Simultaneous Machining: 4-Axis simultaneous machining is an advanced manufacturing technique that allows CNC machines to operate on four axes (X, Y, Z, and an additional rotational axis) simultaneously. This enables the production of complex geometries and intricate designs that would be difficult or impossible to achieve with traditional 3-axis machining.

In a machining engineering business, 4-axis simultaneous machining services enable the creation of highly precise and intricate components for industries such as aerospace, automotive, and medical, where complex geometries are often required.